source:silicone plate manufacturers release time:2022-07-13

There are various materials for silicone products. In addition to mixed vulcanized silicone, it is also widely used in the glue filling process. Two-component condensation type room temperature vulcanization mold silicone rubber is a common room temperature vulcanization silicone rubber. Its raw rubber It is usually a hydroxyl-terminated polysiloxane, which is combined with other compounding agents and catalysts to form a rubber compound. The viscosity of this compound can range from 100 centistokes to one million centistokes. There are two types of flowability and semi-flowability, which can be used for potting and coating. The product can achieve high transparency.

1. Product use

The vulcanization time of the two-component condensation type room temperature vulcanization mold silicone rubber mainly depends on the type, amount and temperature of the catalyst. It takes about a day to fully cure at room temperature, but only 1 hour at 150°C. It can maintain elasticity for a long time in a temperature range of 65~250 °C, and has excellent electrical properties and chemical stability, water resistance, ozone resistance, weather resistance, and simple usage. Sealing and molding materials. Various electronic and electrical components are coated and potted with room temperature vulcanized silicone rubber, which can protect against moisture, corrosion and shock. Performance and stability parameters can be improved. Two-component RTV silicone rubber is especially suitable for deep potting materials and has a faster curing time, which is superior to one-component RTV silicone rubber products.

Two-component RTV silicone rubber has excellent anti-stick properties after vulcanization, and the shrinkage rate is very small during vulcanization. Therefore, it is suitable for making soft molds for casting epoxy resin, polyester resin, polystyrene, Molds for polyurethane, vinyl, paraffin, low melting point alloys, etc.

2. How to use

1. This product is divided into two components: A and B. The A component is a white paste, and the B component is a liquid curing agent. When using, firstly mix the two components of AB with 20-30:1 (mass ratio), stir evenly, and then use;

2. The surface of the adherend should be kept as clean and free of oil as possible, so as to ensure good adhesion between the silicone rubber and the surface of the product;

3. During the use process, the stirring will bring in air, which will cause bubbles inside. If necessary, it can be defoamed by vacuuming in a sealed container;

4. When the two components, A and B, are mixed, considering their operation period, they should be used up within 20 minutes as much as possible;

5. Apply the mixture on the surface of the material and leave it for 24 hours until it is completely cured before use;

Read recommendations:

popular recommendation

Starfish baby teether

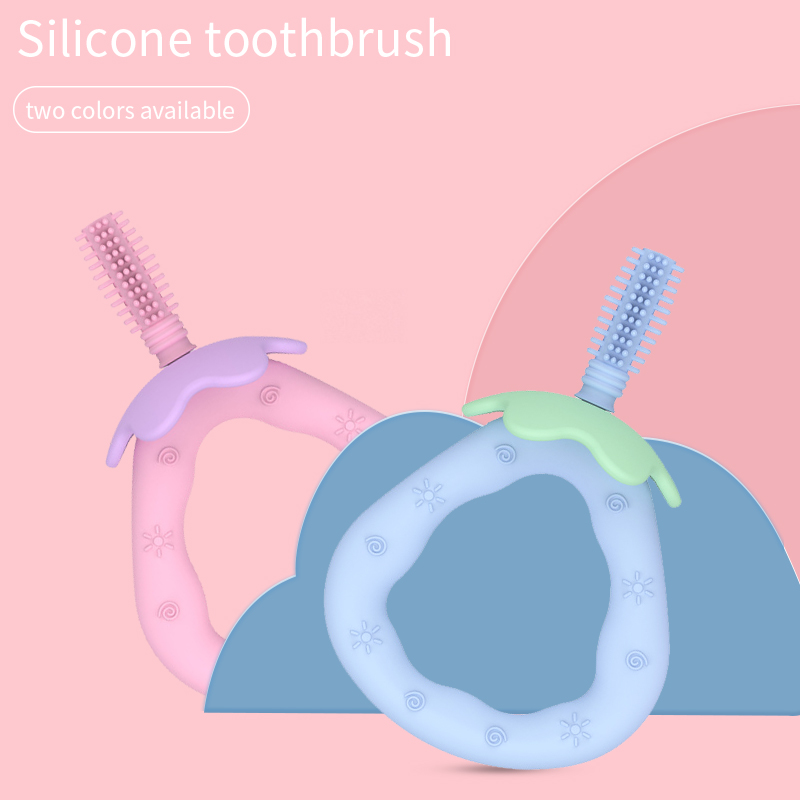

2022-01-08Baby silicone toothbrush

2022-01-12Needle tube type medicine feeder

2022-01-12Silicone cleaning gloves

2022-04-23Snack cup

2022-01-08Snortseling mask FTA

2022-04-23Silicone pea-shaped packaging bottle

2022-04-23Corn baby teether

2022-01-08Mutifunction foldable compress water bottle

2022-04-23Fire boy teether

2022-01-12baby pacifier feeder manufacturer

2023-04-11newborn baby nipple manufacturer

2023-04-11baby pacifier clips custom

2023-04-11good baby pacifier Processor

2023-04-11pacifier chain gold direct sales

2023-04-11baby food pacifier wholesaler

2023-04-11baby gags on pacifier manufacturer

2023-04-11baby pacifier bibs direct sales

2023-04-11animal pacifier clip sales

2023-04-11newborn baby pacifier Factory

2023-04-11Do pacifiers suck in air and cause bloating?

2022-05-09What is included in the silicone kitchenware,silicone plate mat

2022-05-27Can the pacifier be boiled? bibs baby pacifier manufacture

2022-06-20Are pacifiers necessary?

2022-04-27How to choose a baby bottle? Here's a trick

2022-03-14The right bottle is selected, and the baby easily crosses the weaning period

2022-03-19Baby bottle precautions

2022-03-16Why do silicone products turn yellow after being used for a long time?silicone baby pacifier clip Pr

2022-06-21How to choose a pacifier?silicone teething pacifier clip

2022-05-11How to use the nuk pacifier correctly.silicone baby pacifier clip direct sales

2022-06-20